Computational Modeling & Simulation

ATC uses computational modeling and simulation to streamline design, prove concepts, and reduce development costs. ATC's in-house computing cluster allows for fast-running simulations on a secure ITAR compliant system.

For Armor

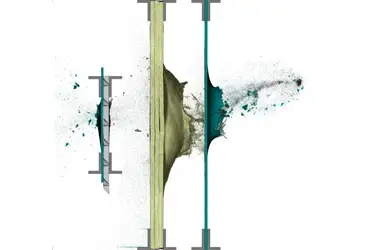

High-fidelity physics-based simulations of projectile impact, armor material behavior, debris cloud geometry, and energetic response predict system behavior and allow for rapid development of design concepts. CTH, ALE3D, and EPIC18 shock physics code are used for high strain rate impact dynamics, blast events, and armor development while Cheetah chemical kinematics code generates equations of state for energetic materials. Combined, these tools allow for computational development of armor and prediction of armor response and reaction rate of energetics in IM scenarios.

ATC developed material models for high-hard and ultra-high-hard steels at strain rates greater than 10E+6. High speed video and x-rays of hundreds of live tests help calibrate models and increase fidelity. Using modeling and simulation, armor can be designed quickly and efficiently and reduce the number of live-fire tests required.

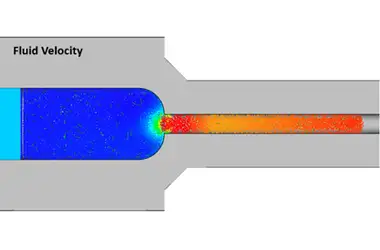

For RF Materials

Computational tools assist in process development and predict finished component performance. Tools including COMSOL and LAMMPS simulate material behavior during manufacture and predict material response reducing development. Mold flow simulations reduce time to develop tooling for complex geometries. Finished component performance may be predicted via static loading aeroheating, and thermal analysis simulations.